BASIS OF DESIGN - TRICHLOROSILANE (TCS)

- 29 Jul 2024

Trichlorosilane (SiHCl3) is a chemical compound that consists of silicon, hydrogen, and chlorine atoms. Trichlorosilane (TCS) is a key chemical used in the semiconductor industry, particularly in the production of high-purity silicon for the manufacturing of electronic components.

TPS provides a total solution for design, QRA, HAZOP, authority submission, bidding, construction management, testing and commissioning, and obtaining a Flammable Liquid storage license. Design will address day to day operation safety, reliability and worst-case release of TCS.

Total Process Systems (TPS)Pte Ltd

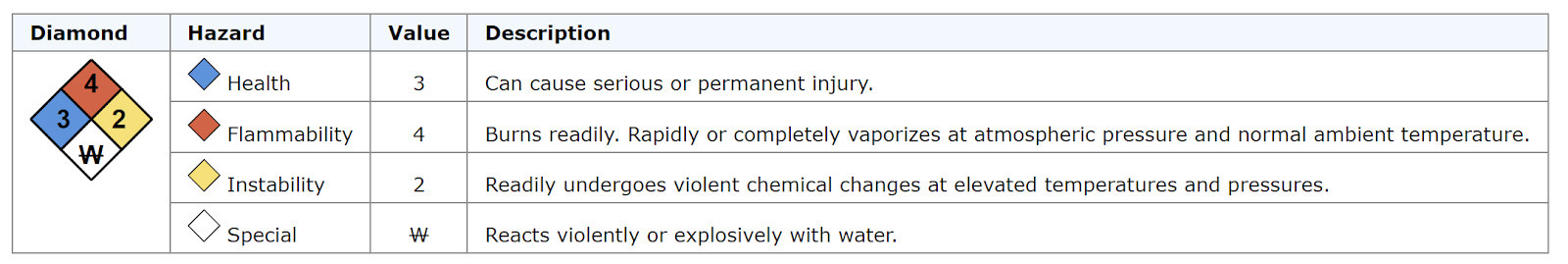

HAZARD

Trichlorosilane(TCS) is a pyrophoric liquid. A highly flammable, toxic and corrosive liquid. It reacts violently with water & air to generate heat, flammable (H2) and corrosive (HCl) gases. It has a Lower Explosive Limit (LEL) of 1.2% and an Upper Explosive Limit (UEL) of 90.5%.

TCS combusts to form a hazardous mixture of Chlorine and Hydrogen Chloride (HCl) gases. (SiHCl3 +O2 = SiO2+HCl+Cl2)

TCS reacts with water to form Hydrogen Chloride (HCl) and Hydrogen Gas. (SiHCl3+H2O= SiO2 + 3 HCl+H2)

TCS has hazardous properties of low flash point (-27°C), easily combustible, water-reactive and acid-producing which created many difficulties in response as it leaked out.

SUPPLY SYSTEM (BULK CHEMICAL DELIVERY-BCD)

To ensure a continuous and safe supply of ammonia, TPS provides a robust gas supply system:

- Typical TCS available Durm capacity – 250Kg

- System A and System B Automatic switch over Gas Panel to provide continuous supply.

- TCS delivery to tool by pressurising gas N2, H2 etc depending on the process requirements.

- Automated PLC/ Touch screen changes out procedure.

- Dedicated Purge Panel c/w purifier filter. He-5%/N2 typically has moisture content of 2pmm, install purifier c/w filter at purge panel.

- Provide Excess Flow Switch (EFS) at pressurization line

- Purge Abatement

- Provide two sources of electrical power. (UPS and Normal)

DESIGN REQUIREMENTS FOR TCS STORAGE ENCLOSURE SYSTEM

Use only SEMI-S2 certified by a third party, such as TUV Cabinet. The Design should also meet UBC/UFC requirements.. The bottom, top, door and sides of the cabinet shall be at least No. 12 gauge (2.5mm). All welded construction must be rated for Class 1 and Div 2 services. Provide provision to ground (ESD Bonding) the cabinet.

Provide the spill containment capacity within the cabinet at 120%. Provide two leak detectors in the spill containment. Leak Detector in secondary Containment will activate audio and visual alarm at enclosure and to Gas Monitoring SCADA.

Provide continuous exhaust for the cabinet, maintain the cabinet exhaust pressure at 200 PSI, and monitor the exhaust pressure at Gas Monitoring SCADA. Exhaust will operate in fire mode

Provide a rate of rise (ROR) to monitor the increase in temperature and UV IR to monitor the fire.

Provide K80 68°C quick response sprinkler connection at each container space.

Cabinets are provided with self-closing doors ensuring that the System will not be operated with the door in the open position. Fire-reinforced access window should be 6.5mm (0.25in) thick wired safety glass. All surfaces should be free of burns, sharp edges and other flaws that could injure users. The Door and window should be self-closing and self-latching. Door should be tight closing and sealing. Gaskets should be provided on all doors, access ports and other penetrations. Tight seal penetrations. Joints shall be welded, and doors shall be provided with a three-point latch arrangement.

Alarms and Signals: Activation of the fire detection system will initiate a local alarm in the building and transmit a signal to FCC Room. The alarm shall be both audible and visible.

Local Emergency Manual Shutoff (EMO) is provided, and Remote EMO is provided at TGM Room

Chemical Label: A label clearly displaying the Chemical formula and common name of the Chemical should be attached to the enclosure exterior surface, its color will contrast with that of the enclosure

Hazard Warning Label: A label clearly displaying the Hazard warnings should be mechanically attached to the enclosure exterior surface. To follow SS586:2014 Part 2

CIVIL, STRUCTURE & ARCHITECTURE (CSA)

TCS is a pyrophoric and reactive liquid. Safety is paramount in our approach. The Structure architecture includes:

- 4-Hour Fire Rated Walls: Passive fire protection on three sides thus any fires will be contained within a 4-hour fire compartment.

- 4-Hour Door: Passive fire protection at the front for TCS Drum Handling.

- Closed System: To contain any potential leaks

- Trench: Provide trench along the edges of the TCS Room to capture possible spillages

- Retention Basin: To collect firefighting water and prevent contamination

- ESD Floor: Provide ESD floor to prevent accumulation of static electricity.

FIRE

TCS pyrophoric liquid will ignite spontaneously without the presence of an ignition source when exposed to air. The main leak detection safety devices are UV and IR. Install UV-IR within the TCS storage cabinet and room

The UV/IR device combines a UV and an IR flame detector in one device to respond to flame conditions. This will provide an early indication of a leak in the process container area. When the fire is detected by the UVIR inside the cabinet, TCS Supply will be shut down.

Install High Temperature Sensor within the TCS Storage cabinet. The sensor will trigger a shutdown when a rise of 40°C is detected in a period of less than one minute.

In addition to gas monitoring systems, link these alarms (UV, IR, and rate of rise) to life safety systems to alert the PA System and ERT Team.

TCS is water reactive, hence uses the Low expansion Foam sprinkler system. Use K80 Quick Response 68 °C sprinkler. Piping is filled with foam solution so there is an immediate discharge of solution when the sprinkler operations. Design the Foam system as per NFPA 11 and 16.

- No open flames, No sparks, and No smoking.

- Closed System, Ventilation, explosion-proof electrical equipment, and lighting.

- DO NOT use compressed air. (CDA) for filling, discharging, or handling.

- Manual Call Point., Fire Alarm (Bell & Strobe) and Link to Overall Fire Alarm Systems.

- Hose Reel

- Fire Extinguisher

- Fire Hydrant

LIFE SAFETY SYSTEMS

- Install H2 and HCl Gas Detectors at Gas Panel, VMB, Tool Enclosure Exhaust and Environmental Leak monitoring.

- EMO Button.

- Life Safety strobe light and sounder

ELECTRICAL

- Ex-Proof Electrical Fittings.

- Earthing System for Gas Y Ton Cylinder.

DISTRIBUTION PIPING

- Use Stainless Steel 316L EP 10µin COAX piping.

- Annular space filled with Nitrogen and monitor the pressure.

- Insulate the distribution line.

TCS SCRUBBER EXHAUST

Worst case scenario of TCS Drum failure, the contaminated gas room air (HCl, Cl2 & H2) will be directed to the TCS scrubber at the rooftop before venting to the atmosphere. The outlet of the scrubber is to be maintained below < 11 ppm. Minimum ACH for the flammable storage room is 20 and the room is maintained at negative pressure.

TCS Storage room is negatively pressurised to prevent leaks from the room. All the gas leaks from TCS Room (H2, HCl, Cl2) shall be vented out through the exhaust.

Provide Adequate air change for TCS Storage room to keep the flammability limit of the gas below LEL. Vapour Cloud Explosion (VCE) scenarios occur due to a build -up of flammable gas followed by a delayed ignition. With the presence of the exhaust system during the fire mode, the flammable gas in this case H2 is constantly extracted out through the exhaust duct, which prevents H2 gas build-up

- Ducting Material FM Approved ETFE

- Provide N+1 Exhaust Fan

- Emergency Power Source for Exhaust Fan

CODE COMPLIANCE

- SCDF Fire Code 2023

- Workplace Safety and Health Act

- SS 532:2016 Code of practice for the storage of flammable liquids

- SS 593 Code of Practice on Pollution Control

- SS603 Code of practice for hazardous waste management

- NEA Pollution Control /NEA Emission limit – 11 ppm

- BCA

- Insurance Company safety requirements

- NFPA 318: Standard for the Protection of Semiconductor Fabrication Facilities

- NFPA 30: Flammable and Combustible Liquids Code

- FM Data Sheet Semiconductor Fabrication Facilities. (7-7)

Besides complying with the codes and standards, TCS Systems designs additional risk reduction measures to reduce the risk to ALARP level.